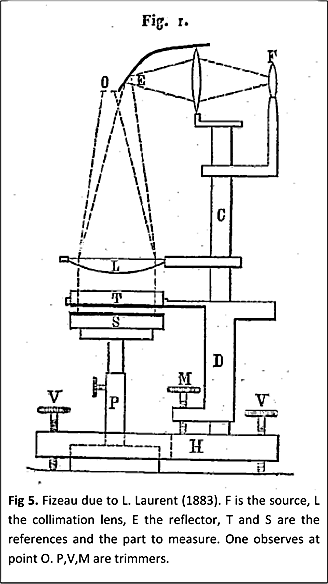

In this blog the measurement of spherical and flat optics with a Fizeau interferometer that have been spot polished is discussed.

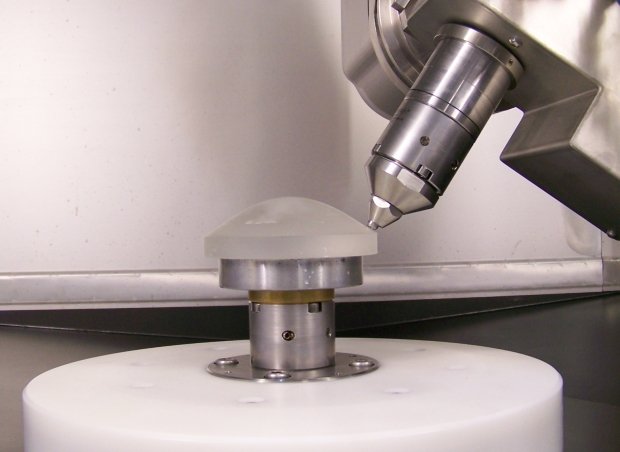

Spot polishing machines for rapid manufacture of standard and high accuracy spheres place new requirements on interferometer systems. The spot polishing method can create small ripple in the surface while shaping the overall form. Accurate positioning of the polishing spot is required to correct the surface errors to bring the surface into specification. To guide the spot polishers image distortion, resolution, and pixel scaling (calibration) are important These requirements primarily drive the imaging system of the interferometer. Continuous zoom system do not meet these requirements.

Modern Imaging Systems

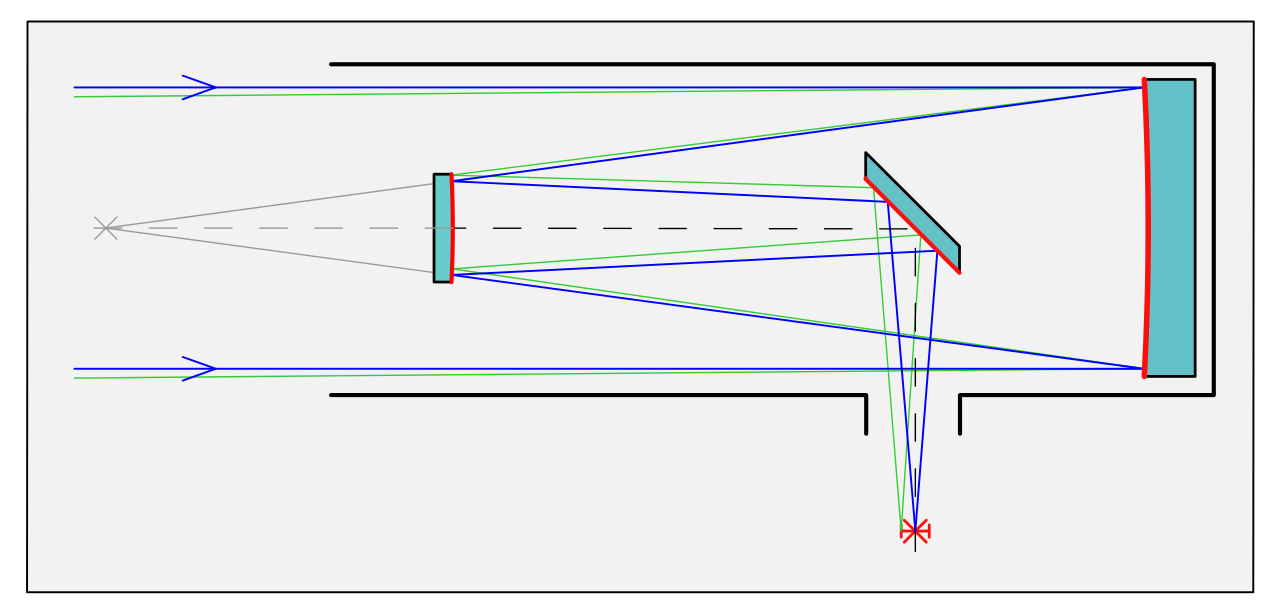

Modern interferometers have discrete or fixed magnification imaging to improve resolution, and minimize distortion and ray tracing errors. All the interferometer optics are exposed to coherent laser light which highlights surface defects. Therefore the optics must be high quality to supress bulls eye artifacts (stray fringes) from scratches, pits, dust and reflections. These hight quality optics increase the system cost.

Interferometer Image Resolution

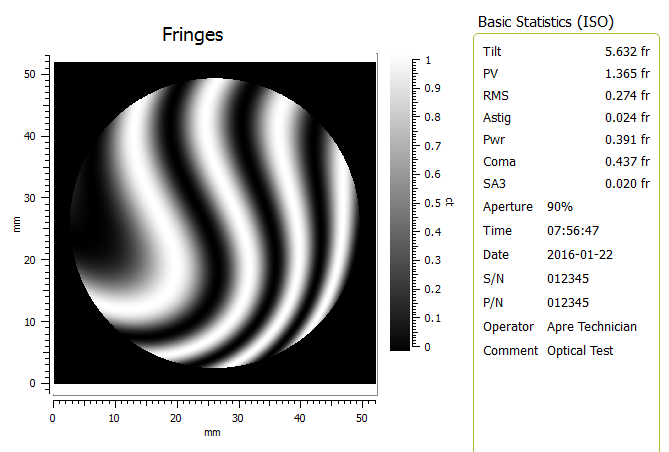

Increased resolution is required to measure mid-spatial frequency surface features. These features can be defined as the residuals present after the removal of 36 Zernike polynomial terms (see REVEAL analysis screen below, the image on the right are the residual mid-spatial frequencies). Mid-spatial frequencies in an optical surface scatters light degrading the image or lowers directed energy concentration. Therefore they must be measured and corrected.

Mid-spatial frequencies are measured with a high resolution imaging system. Typically greater than a megapixel camera is required. The resolution is limited by either the optical design or the camera resolution. If the camera limits then the smallest feature measurable is approximated by 80% of Nyquist frequency

Mid-spatial frequencies are measured with a high resolution imaging system. Typically greater than a megapixel camera is required. The resolution is limited by either the optical design or the camera resolution. If the camera limits then the smallest feature measurable is approximated by 80% of Nyquist frequency

(1-line/mm:2 Pixels), or ~400 lines/aperture for a megapixel camera. At 50 mm field of view, approximately 125 µm feature can be imaged. Continuous zoom interferometers are limited to <100 lines/aperture.

Interferometer Image Distortion

Image distortion maps a surface feature in the wrong position, and the polisher will move to the wrong position. In the best systems the camera limits resolution. As noted 400 lines/aperture is the practical limit of resolution in a megapixel camera, so distortion of 1/400 or 0.25% is required. The polishers polishing function might decrease this requirement, but with 0.25% the interferometer will not be the limiter. For higher resolution cameras the 80% Nyquist again drives distortion… more pixels better distortion requirements, yet practically the polishing function (the shape of the polishing spot) is the limiter. Continuous zoom systems can exhibit up to 2% distortion – 10X higher than modern interferometers.

Interferometer Ray Tracing Errors

When the test part deviates from a sphere many fringes are seen. These fringes indicate high slopes between the reference and test wavefronts. When high slopes occur the test and reference wavefronts traverse different paths through the imaging optics. These divergent paths create wavefront errors in an uncorrected interferometer system. This error can be measured by acquiring data with a null interference cavity, saving the data and then acquiring data with the maximum number of tilt fringes that can be measured and subtracting the two results. The residual error will primarily be due to ray tracing errors and is seen as coma and astigmatism, and sometime spherical aberration. In the old continuous zoom systems thes

e errors can be as large as a wave of error. Even for the small amount of slopes they can measure.

To speed the convergence of the polishing correction process minimizing these ray tracing errors are required. Only the highest quality systems are corrected for ray-trace errors.

Summary

For spot polishing of spherical and flat components a low distortion, high resolution interferometer with low ray trace errors is desired.

Next Post: Next we discuss special applications, starting with Harsh environments