Click here to read an detailed history

In this blog a brief historical outline of the Fizeau interferometer is presented.

Understanding the history of the commercial laser Fizeau interferometer helps to understand the choices available in today’s market. Some systems available today are remnants of historic designs.

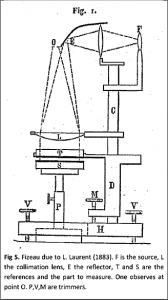

Circa 1850: Fizeau Interferometer Invented

- Hippolyte Fizeau invented this interferometer configuration for an 1851 experiment that at the time supported the either-drag theory, later disproven by Michelson, leading the way to Einstein’s theory of relativity

1960’s: Lasers

- Laser Invented paving way for the laser Fizeau, an unequal path interferometer

1970’s: The architecture is established

-

The first commercial laser Fizeau interferometer, named for George Hunter the designer Zygo® invents basic system architecture with sensor (mainframe) and reference (transmission sphere/flat) – the GH Interferometer in 1974.

- Zygo® employs twin-spot alignment, with continuous zoom/rotating ground glass imaging design to accommodate low resolution (Vidicon camera) and off the shelf zoom lens (Mark II, in 1978).

- Fringe following data acquisition introduced to replace visual fringe evaluation.

- Bell Labs invents phase measuring interferometry on a 32X32 array data acquisition using a Vidicon camera, and PDP 8 rack mounted computer.

1980’s: Data acquisition improvements

- Digital detectors (up to 256X256 by the late 1980’s), CCD/CID, and workstation computers introduced.

- Carrier fringe and four camera simultaneous phase measurement invented (SPMI) for vibration insensitive data acquisition.

1990’s: Software advances

-

The First Phase Measuring Interferometer at Bell Labs Enhanced graphics and additional results with faster processing in lower cost personal computers, primarily driven by Wyko and followed by Zygo®

- CCD’s with 512×512 pixels introduced – no changes to the ground glass-continuous zoom historic imaging design

2000’s: Data Acquisition and illumination Improved

- 4D Technologies and ESDI successfully commercialize SPMI

- Asphere interferometer introduced: Stitching (QED), Fizeau Scanning (Zygo®)

- 1KX1K custom imaging driven by deterministic, computer controlled spot polishing

- Push to better imaging systems in custom designs

- Lower spatial coherence illumination (ring) introduced to improve measurement accuracy

2010’s: MegaPixels + Low Ray Trace Errors + Improved imaging

- First newly designed interferometer optical systems that break the ground glass-continuous zoom historic design for high-resolution, low distortion imaging plus minimized ray-trace errors for improved accuracy with steeply sloped wavefronts from mild asphere optics

- Sub-nyquist (ESDI) asphere interferometer introduced

2020 and Beyond: Light Sources and Software

Lasers have dominated since the 1960’, but their limitations are catching up with them. Vertex back reflection fringes limit measurement accuracy, spurious fringe mask mid-spatial frequencies, and lasers are unable to measure domes, plates, prisms due to back surface reflections.

To overcome these limitations low coherent sources have been introduced. Delay line white light sources minimize the back reflections and spurious fringe problem but are nearly impossible to align, like a standard white light source.

ÄPRE’s Spectrally Controlled Interferometry (SCI) retains the ease of use of a laser with a long coherence mode and then switches to short coherence (white light) mode at camera frame rates. SCI can also measure the cavity distance enabling the measurement of radius of curvature, without the external radius rail, at higher accuracy. SCI looks like the source of the future.

Software

The control of the entire measurement process will become possible with every interferometer using the same measurement setup via centralized control without variation user to user. Software will guide the user as to whether a part passes or fails, and databases will track parts through manufacture and data will be reported consistently, all enabling better process control and thus improved parts.

Summary

The Fizeau interferometer has a long history and promising future. Contact ÄPRE to discuss your interferometery needs to apply the best source + interferometer to your application.

In the next post we’ll explore what is an appropriate interferometer for lap polished flats, spheres and prismatic components.