The laser Fizeau interferometer has experienced several transformations from its original design. Like all evolutionary processes, some vestigial design elements remain in commonly used interferometers, which do not address and can impede measurements required to control and optimize today’s optical manufacturing processes.

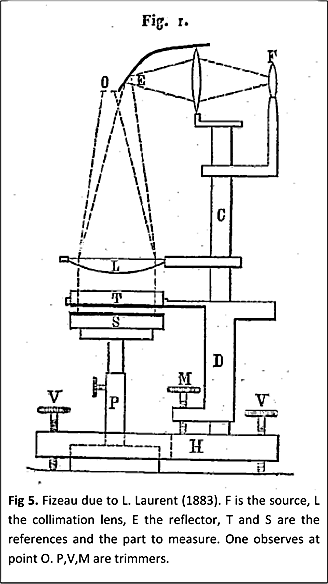

Circa 1850: Fizeau Interferometer

Armand Hippolyte Louis Fizeau (1819 – 1896) invented the interferometer configuration, now named after him, for measurements of glass parameters which he presented at the French Academy of Sciences in 1862. Earlier, in 1851 he used a version of this interferometer in his famous experiment devised to test the ether-drag theory. The results seemed to support a partial ether-drag, that were later confirmed by Michelson and Morley. In a twist of fate the ether theory was disproved shortly after by the more famous Michelson-Morley experiment, but the results of BOTH of these experiments lead the way to Einstein’s theory of relativity. “Einstein later pointed out the importance of the [Fizeau] experiment for special relativity, in which it corresponds to the relativistic velocity-addition formula when restricted to small velocities,” Wikipedia

Pre-1960’s

Before the invention of the laser in the 1960’s optical test interferometers were difficult to use and often had to be custom built for each application. Low-coherence illumination favored equal path interferometers like a Twyman-Green or Mach-Zehnder configuration. The Fizeau – though already commercially available – were large, very heavy, difficult to use and limited to measurements of flat surfaces.

The most popular interferometer, though rarely considered one, is the Test Plate using Newton’s Rings. A test plate is strikingly similar to a Fizeau configuration with only several micrometers of working distance. The test plate consists of one reference surface for each surface an a low coherence filtered source

1960’s – The Laser becomes Practical

The laser made interferometry much easier to implement. “Bob Hopkins…was quick to realize how much the laser could be used to improve the testing of optical components” (J.C. Wyant, “Short history of interferometric metrology”). With the laser, fringes were easy to find making interferometry a practical tool supporting optical manufacture. Much progress was made in testing configurations, yet interferometry remained an experts tool, custom made for the application and developed and run by engineers and scientists. Plus to use a HeNe laser, the most widely available required stabilizing it to have only one frequency of output. Low cost unstablized HeNe lasers had short coherence, around 200 mm and were limited to use in a Twyman Green configuration where the test and reference could be balance. These stabilized lasers were very expensive, in 2020 dollars they would cost $35,000!

1970’s – The Modern Fizeau Architecture is Created

What is now considered a Fizeau interferometer was created in the 1970’s by two different events: The invention of the modular Fizeau interferometer with a laser source, plus computerized phase measurements.

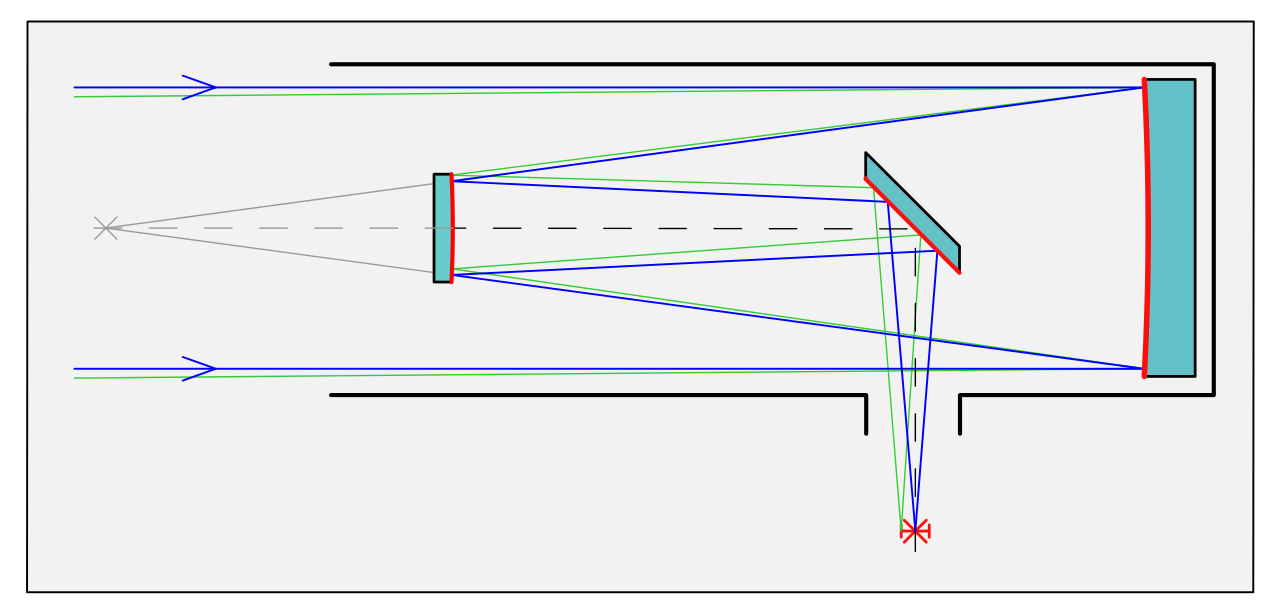

The Fizeau Optical/Mechanical Architecture

The HeNe laser promised to make interferometers much easier to use, but its cost blocked interferometers from becoming a commercial success. The key insight at Zygo that enabled the modern Fizeau interferometer design was that a simple polarizer in front of a multi-mode, low cost laser produced meters long coherence. This insight was applied in 1972 by Carl Zanoni and George Hunter at ZYGO constructing the GH (for George Hunter the principle designer) and the follow-on Mark II™ in 1976 when modern interferometry was born.

It is important to understand the architecture of the Mark II™ to know WHY interferometers are designed as they are today. The ZYGO innovations were a low cost, long coherence laser, a flexible optical architecture, a simple alignment system, with a clean fringe image. The architecture combines an interferometer (“mainframe” in ZYGO terminology in a nod to the 1970’s Tektronix Oscilloscope architecture) with quickly interchangeable reference lenses/reference-surfaces they named transmission spheres (TS) and transmission flats (TF).

With the long working distance due to long laser coherence one TS eliminated the need for large libraries of Test Plates – bringing cost savings and convenience. Plus Test Plates are used in virtual contact, separating the optical test surface from the reference surface eliminated the possibility of scratching and damage.

Ease of use was augmented by the alignment system. The twin spot alignment visually indicated when the cavity alignment was close enough for interference fringes to be found. Now non optical engineers could align and configure an interferometer.

The imaging system of Mark II™ REQUIRED a zoom lens to measure a wide range of part diameters since the only imager available was a vidicon camera. Both the zoom lens and the vidicon produced back reflections and secondary fringe patterns. The solution was a rotating ground glass, “coherence buster”, at an intermediate image that was then imaged incoherently through the zoom lens and onto the vidicon.

Mark Interferometer Design Limitations

This design was so successful that even today’s interferometers with ground glass and 6X zoom are IDENTICAL to the optical system designed for the Mark II™. This is important to understand since the original optical system was designed for a vidicon camera AND only considered the visual measurement of spherical and flat optics manufactured with pitch polished processes.

If a megapixel camera is used in this design, the magnification by the zoom lens is empty, meaning resolution is not increased and potentially degraded. Further, imaging distortion of one or two pixels at 128X128 was acceptable but is problematic when spot polishing techniques are employed that require interferometer feedback for correction. These limitations lead to the development of fixed or stepped magnification imaging systems in the 2000’s, to be discussed later.

The historical influence of the Mark II™ optical architecture cannot be underestimated. All commercially successful interferometers follow the laser + “mainframe” + Transmission Reference architecture. Plus commercially successful alternative optical imaging design were only developed in the 2000’s, where even today (2018) historical inertia drives buying decisions.

The Data Acquisition System

Bell Labs patented computer data acquisition phase measuring interferometry. John Bruning and Donald Harriott’s group and Tropel (now CORNING) worked together to develop the a phase measuring system.

In the 1970’s Bell Labs was pushing the leading edge of semiconductor manufacturing technology. Lenses to support semiconductor manufacture were difficult to build due to their, at the time, extreme tolerances. Conventional visual or fringe center data analysis was not sufficient. Minicomputers were available and enabled in-the-lab data acquisition, as opposed to central batch processing of a few years earlier. Add to this signal processing was a core technology at Bell Labs. This combination enabled retrieving interferogram phase, pixel by pixel, an innovation that started the explosion of development that has continued until today.

Phase acquisition was achieved by changing the interference cavity length by λ/4, stopping, capturing a 32 X 32 sampled camera frame, moving another λ/4 step, frame grab…until four camera frames were captured. A simple calculation eliminates the background intensity term and isolates the phase for each pixel. This is commonly called Phase Stepping Interferometry. Phase Stepping was used to minimize errors due to phosphor hysteresis.

TROPEL (CORNING) developed the first commercial computerized Phase Stepping systems. These were vertical laser interferometers that operated in the Twyman-Green and Fizeau mode. Data processing included a 32X32 array data acquisition off a vidicon tube camera.

TROPEL (CORNING) developed the first commercial computerized Phase Stepping systems. These were vertical laser interferometers that operated in the Twyman-Green and Fizeau mode. Data processing included a 32X32 array data acquisition off a vidicon tube camera.

A few years later Jim Wyant at WYKO introduced Phase Shifting, where a phase was continuously swept and not stepped, improving accuracy and measurement speed. This method was enabled by the use of CCD sensors.

1980’s – The Digital Age

Developments in the 1980’s centered upon improving data acquisition. In-fact data acquisition was the locus of improvements over the next 20 years. ZYGO became the dominant provider of interferometers with TROPEL deciding to concentrate on in-house development supporting ultra-high accuracy metrology and application focused systems (to be discussed later).

Digital Cameras

Digital cameras were now commercially available. The ZYGO Mark III™ had a 100 X 100 pixel array CCD and a home built board level computer with a frame grabber, with data acquired using a 4 frame data acquisition algorithm.

Software and Computers Enhance Performance

The second half of the 1980’s saw the development of the ZYGO Mark IV™ with a “high-density processor” system with a 256×256 array CID camera. The Mark IV HDP system was based on ZYGO’s own computer, computer operating system and internally developed Basic-like software language that was then scripted into a user interface. The software package allowed for custom scripting which required intensive software support. The software was slow and expensive to develop, difficult to use and quickly out of date.

In the 1980’s Wyko Corporation emerged to commercialize the phase shifting microscope and then the Fizeau interferometer. WYKO was innovative regarding data acquisition and software. Based on commercially available computers, operating systems and development software, innovative uses of cameras and phase modulators, WYKO data acquisition systems evolved more quickly than ZYGO.

WYKO’s Innovation enabled the industry to quickly see the value of software to present easy to understand data and also employ algorithms to improve the quality and speed of data analysis.

These innovations include color plots, extended analysis in MTF, PSF, and Fourier based analysis that pushed the industry forward.

This competitive pressure drove ZYGO to develop MetroPro™ the program which became the industry standard software for the next 25 years. MetroPro™ was based on Objective-C an early and quickly obsolete programming language. Yet using the object oriented software gave MetroPro™ the flexibility to survive all those years.

The competition between WYKO® and ZYGO® benefited the optics community tremendously as they challenged each other to improve.

Innovation in the 1980’s

Wavelength Modulated PSI

Phase shifting data acquisition require the phase of the cavity to change. Changing the cavity OPL can be accomplish by slightly changing the wavelength [Gary Sommargren], its commercial application was not fully implemented until 15 years later. (Note: cavity phase can also be modulated via phase modulating the source spectrum, see SCI in the 2000’s)

Vibration Insensitive Interferometry

Two significant inventions that would not become commercially successful until the 2000’s were invented in the 1980’s: Carrier fringe [Takeda, H. Ina and S. Kobayashi] and multi-camera frame simultaneous interferometry [Smythe & Moore]. Both of these enable phase measurement at microsecond rates enabling interferometry in vibrating and turbulent environments.

1990’s – Software and Computers Improve Performance

The Personal Computer revolution of the 1990’s and continuous improvements in semiconductor imaging (CCD’s) were the basis of most improvements in the 1990’s. The Mark II architecture was maintained and repackaged, while faster computers, improving software analysis and higher density cameras were added.

Algorithms

A new concentration on algorithms occurred. It was seen that a robust algorithm could compensate for errors in the data acquisition and environment. New multi-frame algorithms [Creath, Degroot] were created throughout this period.

In tangential fields of speckle interferometry, vibration correction algorithms were being developed that would find their way into Fizeau interferometry after 2000. These so called Vibration Tolerant PSI algorithms make Fizeau Interferometry more accurate in environments where data can be obtained but ripple appears in the data.

High Volume Manufacturing

The growth of high volume manufacture in Asia led to new entrants. The relative expense of WYKO and ZYGO systems positioned them in the market as the R&D and QC standards for wavefront measurement and Fujinon and Olympus emerged as the small aperture interferometers providers for surface and wavefront production measurement.

Molded optics, pioneered at KODAK in the USA in the early 1980’s, led to new consumer cameras and optical data storage devices driving the need for high volume asphere metrology. Interferometers were not able to measure these lenses or molds, leading to rise of stylus profilers from Taylor Hobson and Panasonic. It was not until the early 2000’s that interferometers were developed to measure aspheres.

Vibration Insensitive Commercial Interferometers Emerge

In the early 1990’s Dr. Michael Küchel, of Carl Zeiss, developed the Direct 100 laser Fizeau, a multi-wavelength optical interferometer with advanced optical architecture and data acquisition based on carrier fringe. Custom electronics acquired data at frame rates. The Direct 100 architecture is still employed today in some non-commercial applications. Phase Shift Technology also introduced a multi-camera interferometer on a custom basis. The expense of these interferometers limited their commercial success.

New Source Modality Discovered

A “White Light Fizeau Interferometer” was created by Professor Schwider in 1997. The light source was a broadband source with spectral content. The unique result was interference fringes a fixed distance from the Fizeau reference surface.

Modern History

It is difficult to determine what are the “landmark” developments without the passage of time. For the last 18 years we will simply review some of the major technology and products introduced to solve a greater range of application via Fizeau interferometry

2000’s – Data Acquisition, Imaging, Illumination, Aspheres and Workstations

Deterministic optical manufacturing drove innovation in the interferometry market. The dominant manufacturing technique up to the 2000’s was pitch polished spheres and flats, which the old Mark II™ could handle. Now, new spot polishing computer controlled machines rendered the capabilities of old style interferometers insufficient. In order to keep pace with the advances in optical manufacturing, optical polishing production had to be capable of the following:

- Minimizing image distortion for accurate positioning

- Calibrating image size in order to know artifact position

- Contain a high resolution optical system in order to detect the mid-spatial frequencies

- The ability to produce sharp images all the way to the edge of the image in order to minimize coherent artifacts at the object’s edge

- Measure very steep surfaces approaching hemispheres

Imaging Improvements

In order to accommodate the industry’s new demands, the Mark II type instruments had to be abandoned. Interferometers with fixed magnification and low distortion imaging, calibrated image size and high pixel resolution emerged.

Workstations

Integrated workstations were developed primarily in Germany in order to move interferometers out of the quality control laboratory and next to the polishing equipment. The advantage of a workstation was the efficiency of integrating an interferometer directly into the production process to measure both surface form and radius of curvature easily and occupy as little floor space as possible.

Data Acquisition

Vibration Insensitive Commercially Viable

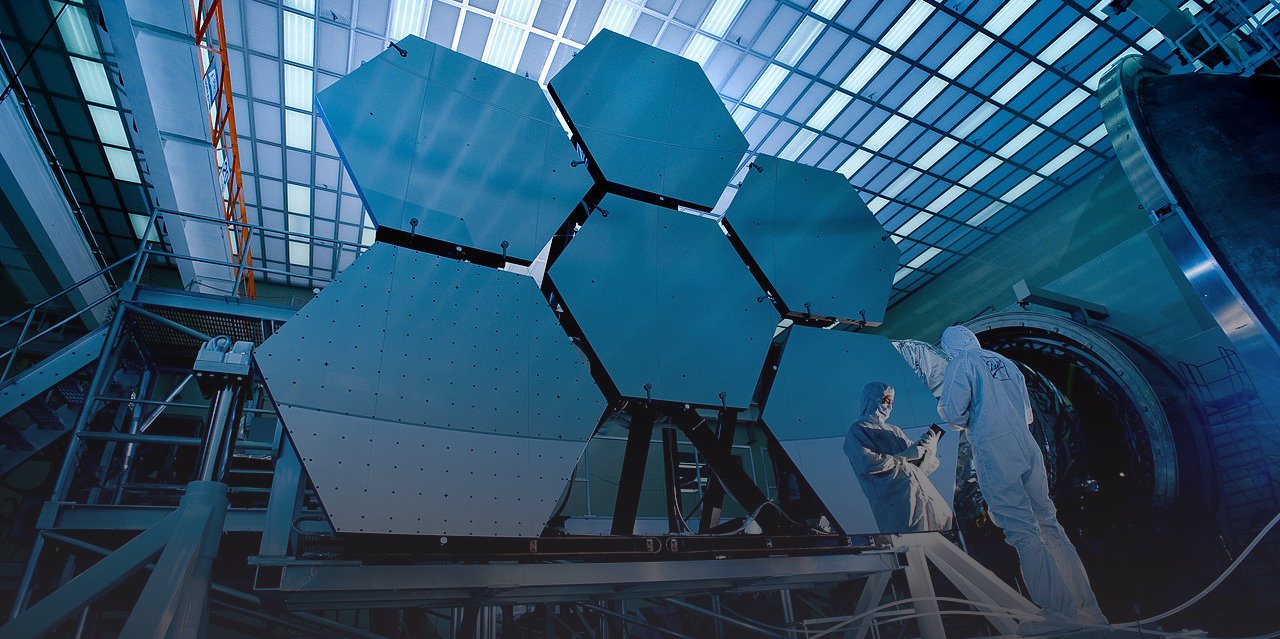

4D Technology introduced a Simultaneous Phase Measuring Interferometer (SPMI) that was the first commercially successful interferometer of its kind. By combining the TROPEL 4-camera approach onto a single detector, the system became robust and easy to use [Novak et. al.]. The expanded manufacture of large mirrors for space and terrestrial application gave 4D Technology an application to establish their business and become a major player in the interferometry market.

A different approach to eliminating vibration sensitivity was developed by ESDI [Szwaykowski et.al.], which introduced the concept of a spatially split source using a high coherency laser in a Fizeau interferometer. This allowed for the simultaneous capture of 3 phase-shifted interferograms.

Carrier Fringe data acquisition also became common as simple PC computers became fast enough to acquire and analyze data sets.

Scanning Fizeau Asphere

An asphere measuring interferometer was introduced by ZYGO. This was a scanning Fizeau [Küchel] that built up rings of data as the part scanned along its optical axis to measure each asphere zone. The zones were then combined to map the as much of the surface as could be accessed.

Stitching of Fast Convex Spheres & Aspheres

QED introduced a practical stitching system [Forbes et.al.] to measure steep, approaching hemispherical spheres. Beside more coverage of steep spheres, higher accuracy due to averaging and potentially higher spatial frequencies were being reported.

Light Source

Several modifications to the point source were introduced in the late 1990’s/early 2000’s which attempted to reduce diffraction artifacts caused by dust particles and other imperfections in the optical system of the interferometer. These were based mostly on increasing the size of the source by projecting a pattern using highly coherent light from the laser onto a rotating ground glass. Such sources with a decreased degree of spatial coherency can eliminate coherent patterns produced by diffraction on small particles and can be very effective, especially when such particles are located far away from the imaging plane.

Scanning Laser Wavelength/Fourier Transform Acquisition

In order to handle measurements of optical components with parallel front and back surfaces, ZYGO introduced a tunable, coherent laser source [Deck] in which the wavelength of light can be swept in a controllable way. This innovation enabled analysis based on a Fourier transformation. Additionally, separate reflections from the front and back surfaces of the sample could be taken in one measurement, which allowed for independent measurements of those surfaces. This method also made it possible to take measurements of the sample optical thickness. This technique is limited to ~1.5 mm optical thickness, limited by the scanning range of lasers. Also the thinner the part the longer the measurement time, up to 60 seconds, making the acquisition vulnerable to environmental vibrations and air turbulence decreasing repeatability of measurements.

Vibration Insensitive/Low Coherence

4D technology introduced a system to solve the long-standing problem of errors caused by vibrations in the machine and testing environment while minimizing coherent artifacts. They used a delay line and a synchronous translation of two components: the reference element and one of the mirrors in the delay line to achieve the vibration-insensitive performance in their model of the Fizeau interferometer. The drawback of such an approach was that it led to complicated architectural design.

Ring Source/Partial Coherence

ZYGO introduced the ring illumination system [ Küchel]. It is similar to a method used by Zeiss [Küchel] in their high performance interferometers. The ring increasingly lowers image artifacts contributions to the measurement the FARTHER the artifact is from image plane. So dust near the launch of the illumination beam is more suppressed than in the reference element. At catseye the ring must be reduced to a spot or no interference is observed due to the wavefront flipping. Similar approaches with a simple enlarged dot illumination are also utilized over shorter optical cavities. The dot could be considered temporally coherent and spatially incoherent.

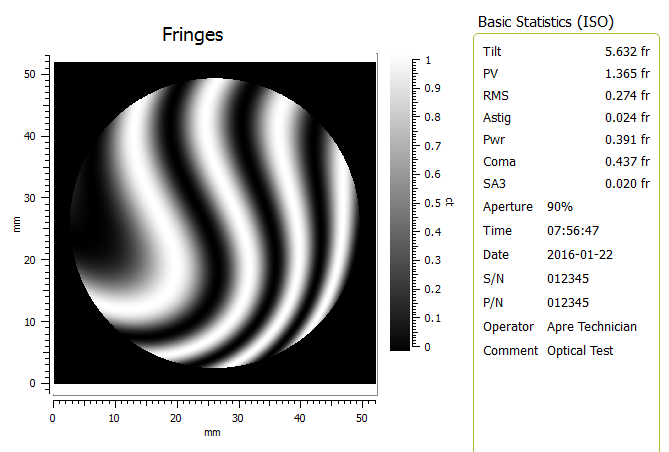

2010’s – High Resolution Imaging, Low Retrace Errors and Spectral Source

CNC polishing machines require rapid and precise feedback between measurement results and fabrication processes. Ideally, an interferometer should be used in a closed loop as a guiding tool in the polishing operation; these needs drive the requirement for low retrace errors, low image distortion, high spatial resolution and acceptance of large departures from “null” condition.

New Interferometer Designs

The older systems, with Mark II™ legacy 6X zoom optics and intermediate fringe images projected on rotating ground glass disks, are inadequate to support CNC polishing applications. In response, 4D Technology and later ZYGO introduced high pixel count interferometers with better image resolution. These systems have better imaging and higher slope acceptance.

Äpre Instruments S-Series Interferometers

Äpre Instruments took interferometer design a step further with balanced optical designs. The HR interferometers for computer controlled polishing applications and the SR interferometers for General Purpose optical shop testing,

HR-High Resolution

ÄPRE S-Series HR interferometers for computer controlled polishing applications or where the highest image resolution and wavefront slopes are required.

- Diffraction limited 2K X 2K spatial resolution (not just pixel count)

- <0.1% image distortion

- <λ/20 retrace errors at 500 fringes of tilt

- Up to 650 fringes of slope across the aperture

SR – Standard Resolution

ÄPRE S-Series SR interferometers are for general purpose optical ship testing. The SR finally replaces the 40-year-old Mark II optical design; outperforming the old design by large measure, without increasing the price to the user.

- Diffraction limited 1K x 1K spatial resolution (not just pixel count)

- <0.1% image distortion

- <λ/20 retrace errors at 250 fringes of tilt

- Up to 375 fringes of slope across the aperture

Surface of Interest Isolation

Spectrally Controlled Interferometry (SCI™)

ÄPRE has introduced a practical SCI source [Olszak], a new source modality to Fizeau interferometry. SCI controls the coherence, fringe position (over 100’s of millimeters) and phase modulation of the fringes electronically. SCI aligns in high coherence mode, like a laser, isolates like a white light source, positions the fringes within the cavity, and phase modulates regardless the cavity size, even down to 50um. By isolating the surface of interest, accuracy is improved and new applications are enabled. This is a new technology and its impact will emerge in the coming years.

Delay Line Surface Isolation

4D Technologies introduced a light source based on a coupled delay-line to project low coherence fringes. Working in a plano-cavity it can place low coherence fringes a distance from the TF and move them over ~25 mm range. Isolating the surface of interest.

Appendix – Hidden Developments

Throughout the history there have been groups developing interferometers whose performance was never made public due to proprietary or classified project constraints, e.g. Perkin Elmer, ITEK, Zeiss, Nikon, Canon, Tropel, etc. Some of these systems were more advanced than available commercial systems, or even disclosed technology in open publications of the time.

Unfortunately these pioneers are not recognized in the open literature, but they too have significantly advanced the state-of-the-art of interferometry and optical manufacturing.

Summary

The Fizeau interferometer has a long history and promising future. Interferometers will continue to evolve as applications and processes drive the need for change and new technologies enable these changes to be implemented.

Contact ÄPRE to discuss your interferometery needs to apply the best source + interferometer to your application.

Note: We welcome your comments or additions to make this history more complete.