There’s no room for downtime or inaccuracies when it comes to optical manufacturing. Interferometers with low imaging resolution and obsolete software cut into profits and damage your reputation by sacrificing time and quality.

Äpre interferometers – both standard and custom – improve your metrology capabilities so you can meet your customer’s demands. Choose from our high-performance interferometers or build the system that works for you.

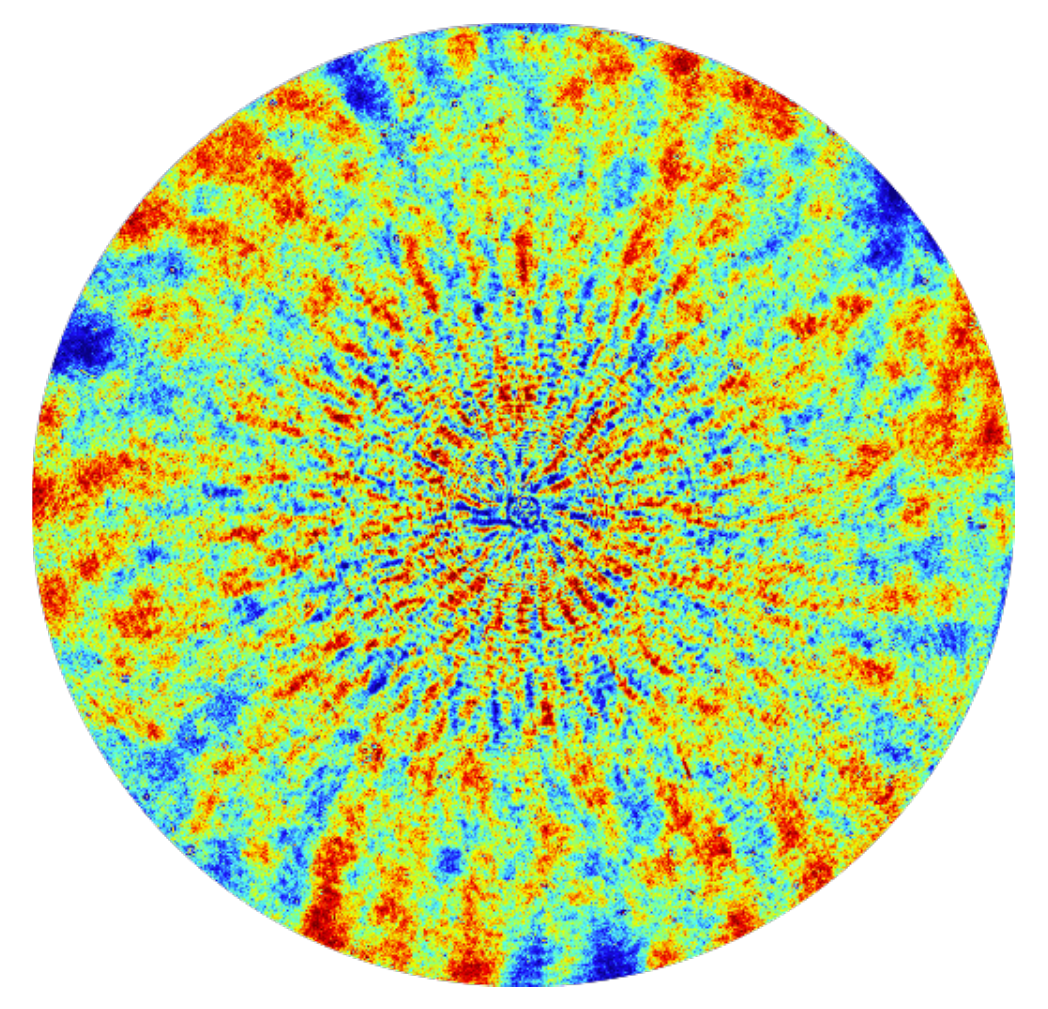

Ä9|9MP Fizeau interferometer enables practical Mid-Spatial Frequency measurement: Advanced camera limited optical design, controlled spatial and temporal coherence, and rapid data acquisition.

Available in bench-top or fully automated systems.

Don’t see what you need? Talk to our engineers about designing your system.

Apre’s Twyman-Green LUPI Interferometer conducts system wavefront testing with the flexibility you need:

Compact, flexible design with

1 Megapixel Imaging

Visual, Vibration Tolerant PSI or Vibration Insensitive Phase

633 nm, 1550 nm or send us your requirement

Don’t see what you need? Talk to our engineers about designing your system.

Made in the USA, Äpre’s optical, mechanical, and radius accessories help you build a complete system or upgrade your existing metrology setup. Our high-quality laser Fizeau reference optics measure polished surfaces (transmission spheres and flats) and system-testing wavefronts and are suitable for CNC spot polishing processes that demand smooth reference surfaces.

Transmission Flats

Transmission Spheres

Reference Flats

Beam Expanders

CGH

Pellicles

Mounts

Mount Accessories

Vertical Workstations

Custom

Guide Rail (manual)

Encoded

Interferometric

SCI – call for information

Do you need to add capacity with a limited budget?

These fully upgraded/refurbished interferometers might be what you are looking for.