Sydor Optics is widely regarded as a world leader in processing and delivering precision flat-surfaced, parallel, and wedged glass optical components. Patrick Drury, Director, Quality & Operational Excellence, Tom Grambo, QA Technician, and John Mandelaro, Precision Optics Manufacturing Technician Apprentice, share how they are using Äpre Spectrally Controlled Interferometry (SCI) to automate and speed the measurement process of the entire part.

When and why did you start working with Äpre?

We’ve been working with Äpre for around seven years. We use interferometers so often in our process, and we have so many pieces of equipment they approached us to beta-test an early version of their SCI interferometer. Apre leads the charge on scanning coherence. Other systems followed suit, but the competing technologies just aren’t the same.

Their service is better than the service of any other system that we have. Äpre has a small group we can collaborate directly with – they’re responsive and eager to try new things. Their team is really good at getting back to us if we have questions on anything software related. Bob visits us to talk about the systems – he’s an owner. We don’t get that level of service from others.

What volumes do you work in?

On a given month, we check thousands of parts. Annually, I’d estimate it at 100,000 parts or more. We have three Apre systems that streamline our processes. On some programs, we test EVERY part, not just a sample, and this type of interferometer saves us 30 minutes per part in some cases. You can imagine how that adds up over time in these volumes.

On some programs, we test EVERY part, not just a sample, and this type of interferometer saves us 30 minutes per part in some cases. You can imagine how that adds up over time in these volumes.

How else does the interferometer save time?

A big time-saver is having the ability to set up and save part-specific parameters using the software. Say you’re measuring a wedge you might forget to change the refractive index. If missed our customers will demand a retest. The software saves us that step because it automatically loads all set up parameters when that specific analysis configuration is loaded. Plus scripting makes the multi-step process 5X faster by taking 4 separate measurements and doing them in one automatic sequence.

Scripting makes the multi-step process 5X faster by taking 4 separate measurements and doing them in one automatic sequence.

Tell us more about the scripting.

We hired John out of MCC’s Optical Systems Technology program. As an apprentice, he moves through every single department. He faced a big learning curve when he landed in the inspection department.

The apprentice program allowed him the time he needed to learn how to use the interferometer. And he just went further down the rabbit hole – he learned it and went the extra mile. He’s been working with Artur at Äpre on writing and implementing code to automate the measurement process so any one of the operators can load the part and run the script.

It’s been a huge benefit to the whole company and has also added to his skillset.

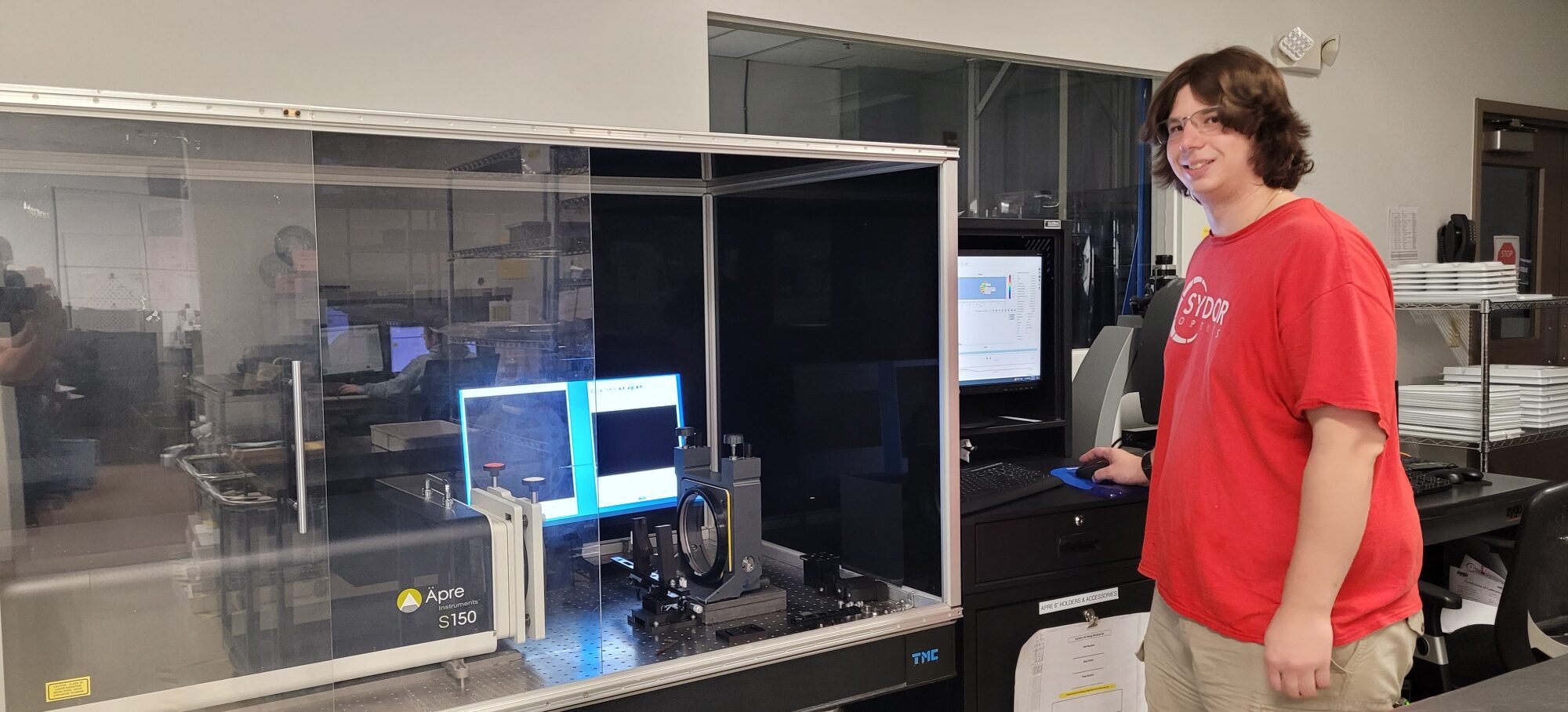

John Mandelaro, an apprentice at Sydor, works on automating their metrology for faster inspection.

How has it changed your experience in optics?

The problem-solving makes it exciting. Just seeing it work, understanding why, and empowering other people to keep projects moving. When you combine all these different skill sets: optics, manufacturing, quality assurance, and even sprinkling in some programming and scripting knowledge, it’s not just a job anymore. It’s a career. You’re changing the space that you’re in.

“When you combine all these different skill sets: optics, manufacturing, quality assurance, and even sprinkling in some programming and scripting knowledge, it’s not just a job anymore. It’s a career.”

Tom Grambo, Sydor Optics