Advanced Optics Require Advanced Interferometers to Improve Processes, Minimize Risk

Today’s leading precision optics manufacturers are learning from past mistakes. Leaders look to boost profitability while adding capabilities that can handle the demands of complex optics and their applications. While it may sound counterintuitive to look back when trying to solve the challenges of your customer’s emerging technologies, the “war stories” from our shared past help shed light on where to invest for maximum gains.

Ever-changing quality standards, especially for today’s complex optics, demand rigorous quality processes and sophisticated metrology instruments that complement and enhance your fabrication capabilities. Optical metrology systems may not seem like a major player in your facility, but as we’ve learned in the past, they greatly affect production processes and profitability.

A Hard Lesson Learned

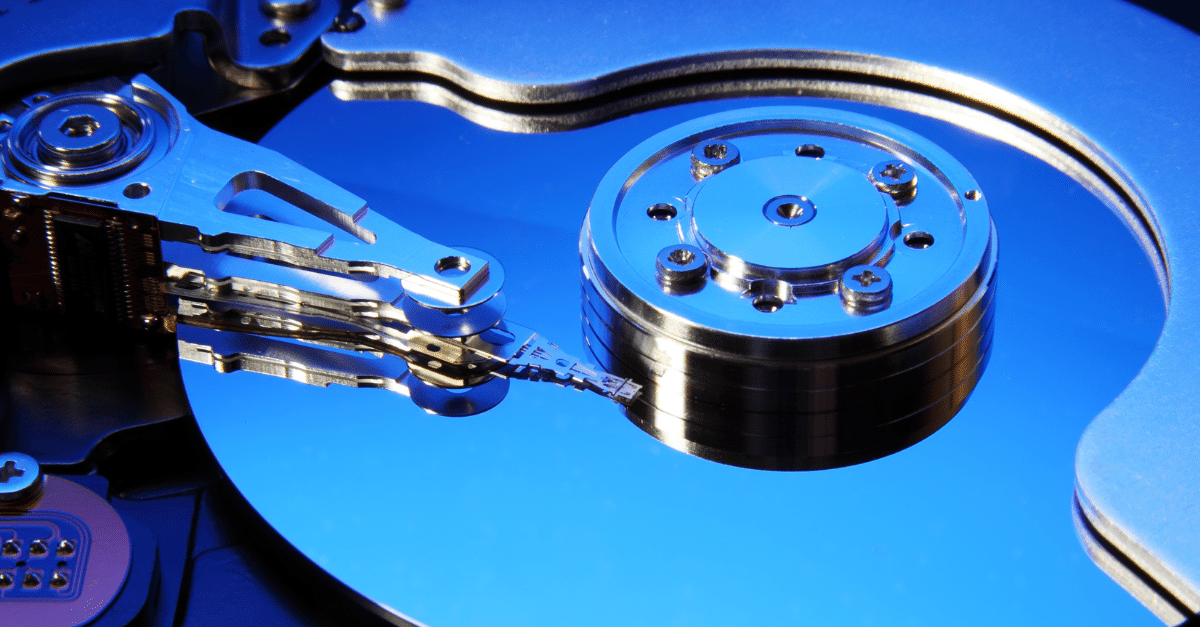

Remember the 1990s, when hard disks required increasingly higher data densities? Manufacturers radically redesigned the air-bearing surfaces between the disc and the read-head, and metrology instruments such as phase-measuring interferometer microscope profilers were instrumental in controlling and measuring these small surfaces.

Several companies bought hundreds of these profilers to measure every read-head because defective air-bearing surfaces led to early disk failure. Other companies thought they could buy a few profilers to control the process statistically and save money.

Here’s where the lesson comes in: when it comes to metrology, cutting corners just doesn’t work. The companies that didn’t invest enough in precision metrology suffered from quality issues that the market didn’t accept. They were all out of business in five years. Companies that used metrology to their advantage and measured every single read-head avoided early disk failure, and are still in business today.

The cost of metrology to those who tried to save money and cut corners? Extinction.

Use Metrology to Differentiate Your Business

The advent of deterministic optical manufacturing by spot polishing has led to new shapes and higher subsequent levels of accuracy. These optical polishing machines can cost hundreds of thousands of dollars; efficiently using these machines keeps costs down and boosts profitability. The manufacturing manager at one of our customer’s sites noted that buying an APRE interferometer to just gain 15% efficiency in manufacturing performance paid for the interferometer in less than a year.

In this case, the cost of metrology is negative. It paid for itself.

APRE’s interferometer led to 15% process improvement and paid for itself in 1 year. Select Your Interferometer.

Don’t Sell Your Optics Manufacturing Equipment Short

With advances in optical applications, specifications are more complicated than 20 years ago. Expensive polishing machines enable these advanced optics and require advanced metrology to measure features that were not present in pitch-polished surfaces, such as Mid-Spatial Frequencies (MSF). Now, control of MSF, slope, and wilder shapes means metrology must improve. Zoom interferometers designed in the 1980s cannot measure today’s optics. What can’t be measured can’t be improved. Therefore, what feels safe is a trap. The cost of not investing in your future is extinction. Maybe not today or tomorrow, but in several years as your competitors pull ahead in both quality and profitability.

“Control of MSF, slope, and wilder shapes means metrology must improve.”

The cost of metrology might seem high when it “doesn’t make anything.” But cutting corners in metrology hinders the capabilities of your advanced manufacturing equipment. Pair your equipment with advanced interferometers to make products faster, better, and meet higher performance specifications. Ultimately, with just 15% process improvement, interferometers quickly pay for themselves. The alternative? View your metrology system as an opportunity to cut costs, all at the risk of your business.

APRE Interferometers was founded on the belief that advancing the field of metrology can advance the field of precision optics. Our eyes are on the horizon—anticipating your customers’ needs for ever-more advanced optics and designing the next generation of interferometers and software with fast, easy reporting. APRE also keeps today’s production going with upgrades of most interferometers and unmatched service. We’re prepared to help you advance your capabilities while keeping today’s production running.