Failing Good Parts? Maybe the Problem is Retrace Error

Retrace error is rarely specified for an interferometer, often ignored and can cause good parts to fail. Knowing how to minimize, decreases scrap, saves time, and lowers manufacturing cost.

Transmitted Wavefront Measurements

Recently an ÄPRE upgrade customer using a 6X zoom interferometer noticed unexplained user-to-user variations. The setup was a window within a Transmission Flat (TF)/Reference Flat (RF) cavity. With the window in place, the operator adjusted the tilt fringes using the reference flat to a user selected number of tilt fringes.

- User-1 observed variations up to 0.04 fr.

- User-2 observed variations up to 0.50 fr, on the same parts!

User-2 was scraping good parts with a 0.1 fr specification!

Root Cause: Measurements Vary with Cavity Tilt

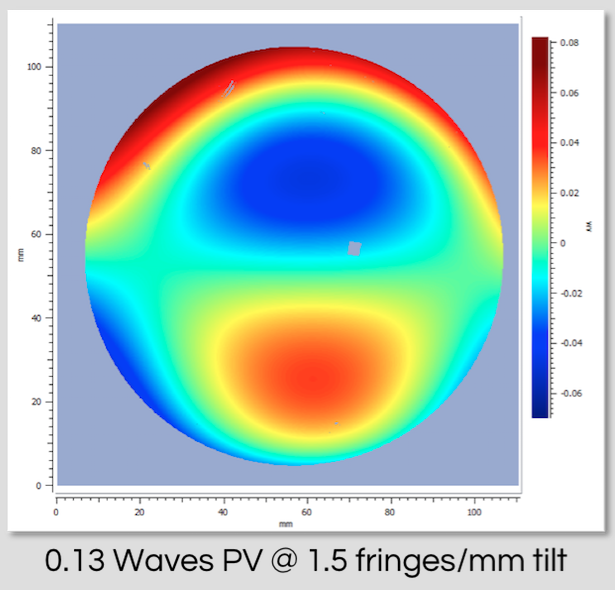

Investigation revealed the root cause of the variation. User-1 adjusted to <3 tilt fringes to near null. User-2 adjusted to 7 to 10 tilt fringes. 7 to 10 fringes was enough to introduce measureable retrace error to cause the variation and falsely failed parts.

In Classic Continuous Zoom Systems, Tilt Fringes Degrade Results

Retrace error is not controlled in zoomed imaging classical interferometers. Consequently tilt fringes degrade results. Strangely even most high-end interferometers today do not specify retrace error. Why not? Retrace error is important to everyday measurements.

Recipe for Best Results: Window Transmitted Wavefront

- Align the transmission flat (TF), ÄPRE Application Note: How to Align a TF

- Align the reference flat (RF) until the fringes are nulled

- This minimizes Retrace Errors

- Measure the cavity without the window

- Save the resulting measurement to the Clipboard

- Subtract Reference (Analysis Tools) with the cavity measurement selected

- Removes TF/RF cavity residual errors

- Place the window into the cavity

- Tilt the window just enough so no window fringes are seen

- Measure and report the results

Retrace Errors also Influence Spherical Surface Testing

The presence of tilt fringes in a classical zoom system will degrade any measurement, even spheres and flats. Only the ÄPRE S-Series minimizes retrace error. An ÄPRE S-Series interferometer, exhibits <λ/20 Retrace Error at 500 fringes! With the S-Series retrace error induced user to user variations are nearly nonexistent.