What accuracy can be achieved with an Interferometer?

Instrument correlation sets a performance base line for metrology instruments. When parts are manufactured and shipped, correlation between vendor and customer is expected. If metrology systems do not correlate arguments ensue regarding who is right.

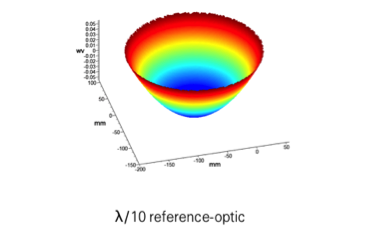

Several years ago I received a call from a quality manager. He was unhappy with the results of a correlation study comparing several interferometers in his factory. The test was simple. He manufactured several parts and measured them on the various systems. Each system was stand-alone and had its own set of λ/10 accuracy transmission sphere reference optics. The temperature throughout the factory was held to ± 0.2C and only trained operators were used. Surprising to the QC engineer, the measurements only agreed to λ/5. 2X worse than expected.

Why?

There is a common misunderstanding that since λ/10 reference-optics are accurate to λ/10 that instruments using them will correlate to λ/10. Yes the reference-optics are accurate the λ/10, that is ± λ/10. Therefore when you compare results they can correlate too much better than λ/10 (down to the instrument noise if low pass filtering is applied) or differ by λ/5, just what the quality manager noticed.

How does this affect vendor quality control and customer inspection?

When measuring spherical and flat optics the measurement uncertainty to first order is determined by the reference optics accuracy. For aspherical optics this is not the case, and might be the subject of a future blog. So lets keep it simple and assume spherical and flat optics are being manufactured. In practice the application of error sources is somewhat more complicated for spherical optics, the following argument is true for flat optics and mostly true for spherical optics. For flats the lowest order error is power, for spheres the errors of interest are 3rd order Spherical, Coma and Astigmatism.

The Vendor

The manufactured part has a tolerance; we’ll assume is λ/2 for this example. When the part is measured the result includes the part shape error and the reference optic uncertainty, an unknown but within ± λ/10. Therefore if the measurement is on the high side it can be as poor as + λ/10 worse, and if on the low side – λ/10 worse than measured.

To be assured the part meets specification it must be manufactured to ± λ/10 tighter tolerance, shown in figure 1. Now the manufacturer knows the part is within tolerance, and is certain they are shipping a good part.

The Customer

Upon receiving the part the opposite is true. The customer has no knowledge of the sign of the reference surface optics error. Therefore the parts must be accepted if the measured surface error is within the tolerance PLUS the reference surface uncertainty as shown in figure 2. The customer must be certain they would only reject out-of-specification parts, and this means opening up the tolerance based on the reference surface accuracy.

Design Tolerances Must Consider Metrology To Assure Optical System Performance

The summing of these uncertainties and the epistemological problem drives optical specifications to tighter tolerance. At some point, about 2X the reference surface accuracy, meeting specification becomes expensive due to the tightened tolerance window. At this point improving the reference surface accuracy will open up the manufacturing tolerance window decreasing manufacturing costs. Three methods are available to improve reference surface accuracy:

- The easy method costs money, purchase ± λ/20 reference optics – or better. This can be cost prohibitive.

- Using a three-flat test or a two-sphere test to achieve “absolute” calibration. This works well in theory. Practically the test must be performed with careful attention to alignments to improve the reference surface.

- The most recent test is a calibration ball where averaging is used to calibrate a spherical reference surface and has shown promise in well defined conditions.

Good Metrology Practice

Understanding the role of reference surface accuracy in optical metrology leads to improved tolerancing, establishing appropriate test procedures within manufacturing processes, and an approach to minimize disagreements between vendors and customers.